CO2

Through the Installation of a co-generation system, we were able to Switch from crude oil to natural gas, this Systems generates enough electricity for the tannery to become self-sufficient and also to generate its own heat. With this Investment, one of our main objectives has been reached and that was to curb the Carbon dioxide Emission. As a member of the Leather Working Group, a Holding Company comprised out of Brands, chemical suppliers and leather manufacturers have the common objective to reduce the Pollution of the leather industry and to increase sustainability.

Innovation

Our Team of technicians constantly engages in developing new, fashionable and sustainable products by using Best Available Technology (BAT). Furthermore, all our chemicals are from REACH-certified manufactures, who guarantee to be working without any restricted chemicals. A Team of chemical technicians work closely with us to produce new products and application methods

Biodegradeability of Leather

we work on the ultimate biodegradeability and

can offer already a compostable leather

- biodegradable ISO 20136

- compostable leather ISO 20200

Carbon Neutrality

- We have a certified carbon footprint by Eco2L.

- we reached 2,76 kg/m² for production (2,94 kg/m² included pre and post production)

- We compensate our CO2 footprint with our certified partner ARKTIK.

- We only purchase green gas and green electricity.

- Co2 neutral produced leather.

Transparency

Transparency in sourcing all material is very essential to us. Not only for the chemicals and hides but also for the working conditions, how they are produced and who worked on them. So a social audlit like Sedex is required from our partners and us.

TRACEABILITY

- Guaranteed provenance to the single hide level (on request)

- Sustainability data

- Animal welfare

- CSR data

- Regenerative farming insight

- the possibility to work with leather from organic farms

- 100 % control of the raw material and supply chain

HOW?

- The unique laser number printed on each hide is the guarantee for full transparency and traceability.

- The number is directly connected with the number from the ear tag of the individual animal.

- We process all data on the animal such as where it was born,where it grew up, animal welfare regulations, CSRdata on abattoir level and of course it's LWG gold certified.

Certificates

LWG Leather Working Group

The Leather Working Group (LWG) is a multi-stakeholder group, comprised of brands, retailers, leather manufacturers, chemical companies and other relevant parties in the leather supply chain, with the goal of raising the environmental performance of the leather industry.

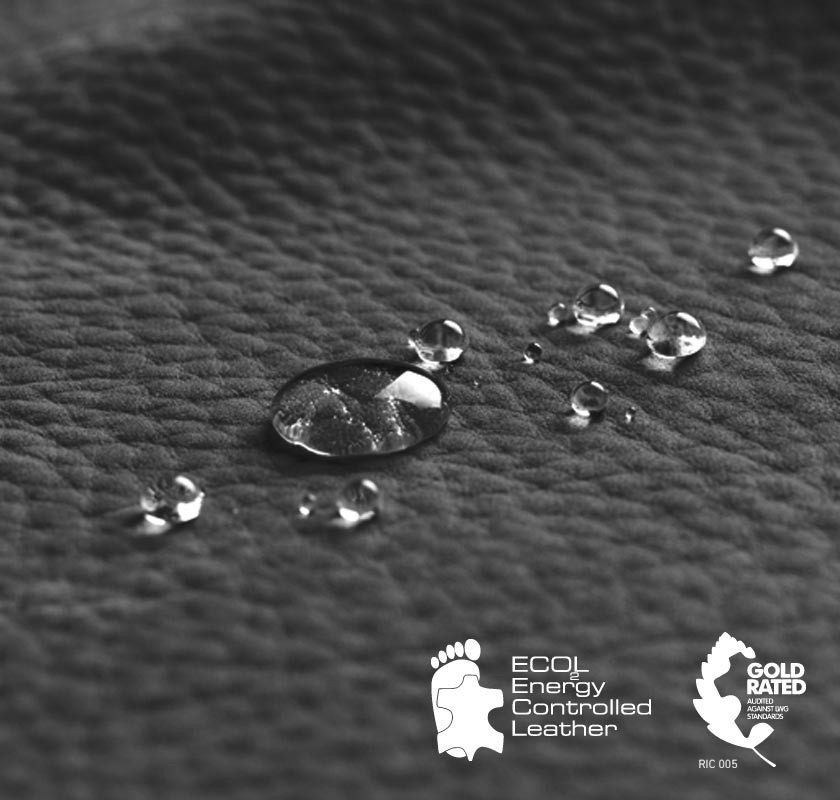

ECO₂L label (energy controlled leather)

ECO₂L is the world’s first calculation and auditing model for determining the energy efficiency and the CO₂-emission of a tannery. ECO₂L was developed by the Forschungsgemeinschaft Leder (Leather Research Foundation) as an active contribution of a responsible leather industry towards climate protection and as a significant aspect to evaluate a sustainable leather production.